With the development of hearing technology, hearing aids into the era of intelligence, phone calls, music, watching TV …… hearing aids for the user’s daily life has brought more convenience.

The cycle of manufacturing a hearing aid from research and development, testing, registration to the market, the cycle needs at least 3 years.

Among them, hearing test is an important part of making hearing aids.

Today, Teng would like to take you to visit the factory to find out how many times a hearing aid needs to be “heard” from the beginning of production to the factory?

Translated with DeepL.com (free version)

Acoustic Laboratory

Research and development is the breeding ground for hearing aids, and it is here that the first hearing test takes place – in the acoustic laboratory.

After outputting a prototype based on various requirements such as appearance and age, a multi-departmental audiometric review team will conduct subjective audiometric testing, scoring the hearing aid in terms of near and far amplification, cacophony, white noise, etc., and generating a test report. On the basis of the report, continuous optimization, improvement and validation will be carried out, and several cycles will be repeated until the test results meet the standards before trial production can be carried out.

Acoustic laboratory related equipment

KEMAR HEAD Artificial Head:

The KEMAR HEAD artificial head is located in the fully anechoic chamber of the Tengnuo Acoustic Laboratory, providing an acoustic full free-field environment. It adopts the HRTF (Head-related transfer function) acoustic model and rotates in four directions to realize the 3D spatial sense of sound. The noise level of the hearing aid on the artificial head is measured in each direction to provide feedback on directional data (e.g. dynamic vs. static differences).

ETSI Acoustic Reverb Room:

“Is this audible? How is the sound level?” The fitter gently beats a drum, the test subject listens with his or her hearing aid, and then gives feedback to the fitter about how he or she feels. Such simulations are often performed at Tengiz.

By simulating the performance of hearing aids in multiple listening environments and evaluating the acoustic performance through such simulations, we are able to debug the acoustic performance of conventional hearing aids, such as conventional acoustic parameters, microphone beams, and signal-to-noise ratios.

Full inspection

Semi-finished product hearing test

After passing the test in the acoustic laboratory, the hearing aid officially enters the trial production stage.

At this stage, the hearing aid undergoes a “listening test” of the component parts.

For hearing aids, every component is critical, and Tengiz knows this.

Therefore, after connecting the receiver to the earpiece, the inspectors need to carefully check whether the power-on tone, volume level, and program prompts of each hearing aid are normal to ensure that there is no small sound, no sound, miscellaneous sound, or broken sound.

In addition, the key feel sensitivity, key normal switching is also within the scope of the inspection; until the results of the hearing test to meet the standards, before the qualified semi-finished components loaded into the electrostatic disk, the finished product “audiometric”.

Finished Product Listening Test

The finished product listening test is based on the semi-finished product listening test and is the last listening test of the full test.

Prior to the objective electrical test, the tester eliminates hearing aids with insufficient gain and output.

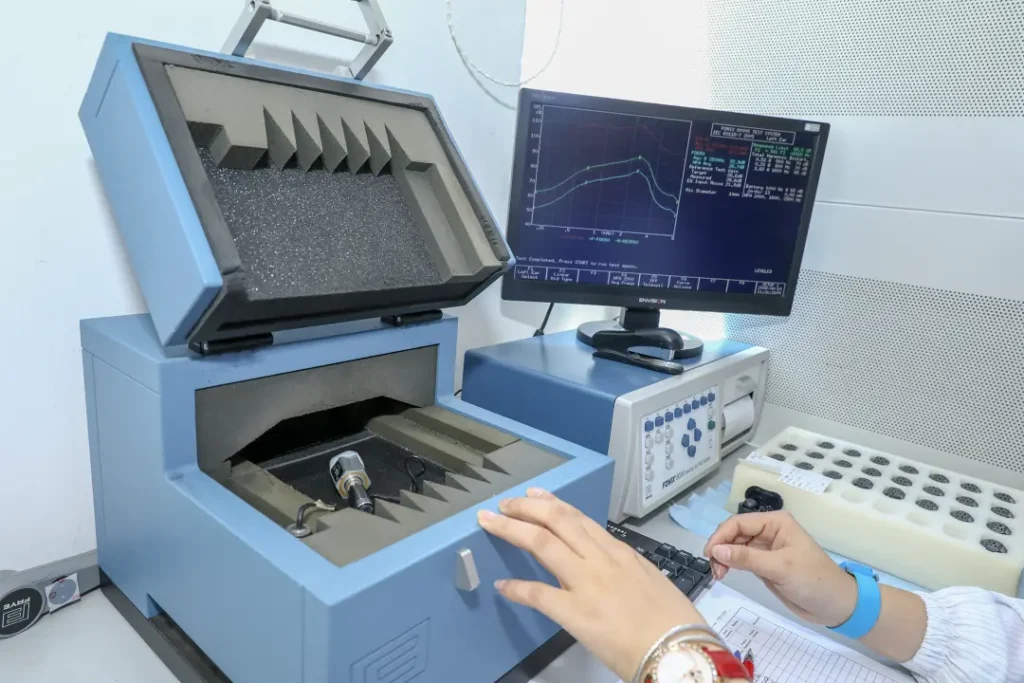

Then, the Fonix 8000 (hearing aid test system) is used to enter the testing phase:

The hearing aid is placed in the test box and the instrument simulates the hearing mechanism of the human ear. According to the parameter requirements, the hearing aid output sound pressure level, full-range sound gain, total harmonic distortion and other performance will be tested, and the test report will be issued.

In order to ensure the accuracy of the test and no mis-testing. Each inspection session requires subjective listening tests in addition to objective electrical tests.

Subjective listening test is more refined, the inspector needs to identify one by one whether there is a sound, or there is more obvious whistling. If the machine is found to have failed to meet the target, it will be returned to the production line.

Sample Inspection

Unlike full inspection, FQC (Final Quality Control) selects a certain percentage of hearing aids for sampling in accordance with national standards to conduct “audiometry” of hearing aids.

FQC is also a two-pronged process of objective electrical testing and subjective audiometric testing to ensure the effectiveness of this part of the audiometric process.

In addition, the tester will check the charging status of the hearing aid several times during this phase.

Hearing aid “hearing test” is not a single link, in the research and development, production, testing in each link “hearing test”, is interlinked, interconnected. Only after passing the “audiometry” test of each link can the product be shipped and become a hearing aid in the hands of everyone. Otherwise, they will be returned to the previous process for reprocessing.

Now do you know how many times a hearing aid needs to be “listened to” from the beginning of production to shipment?